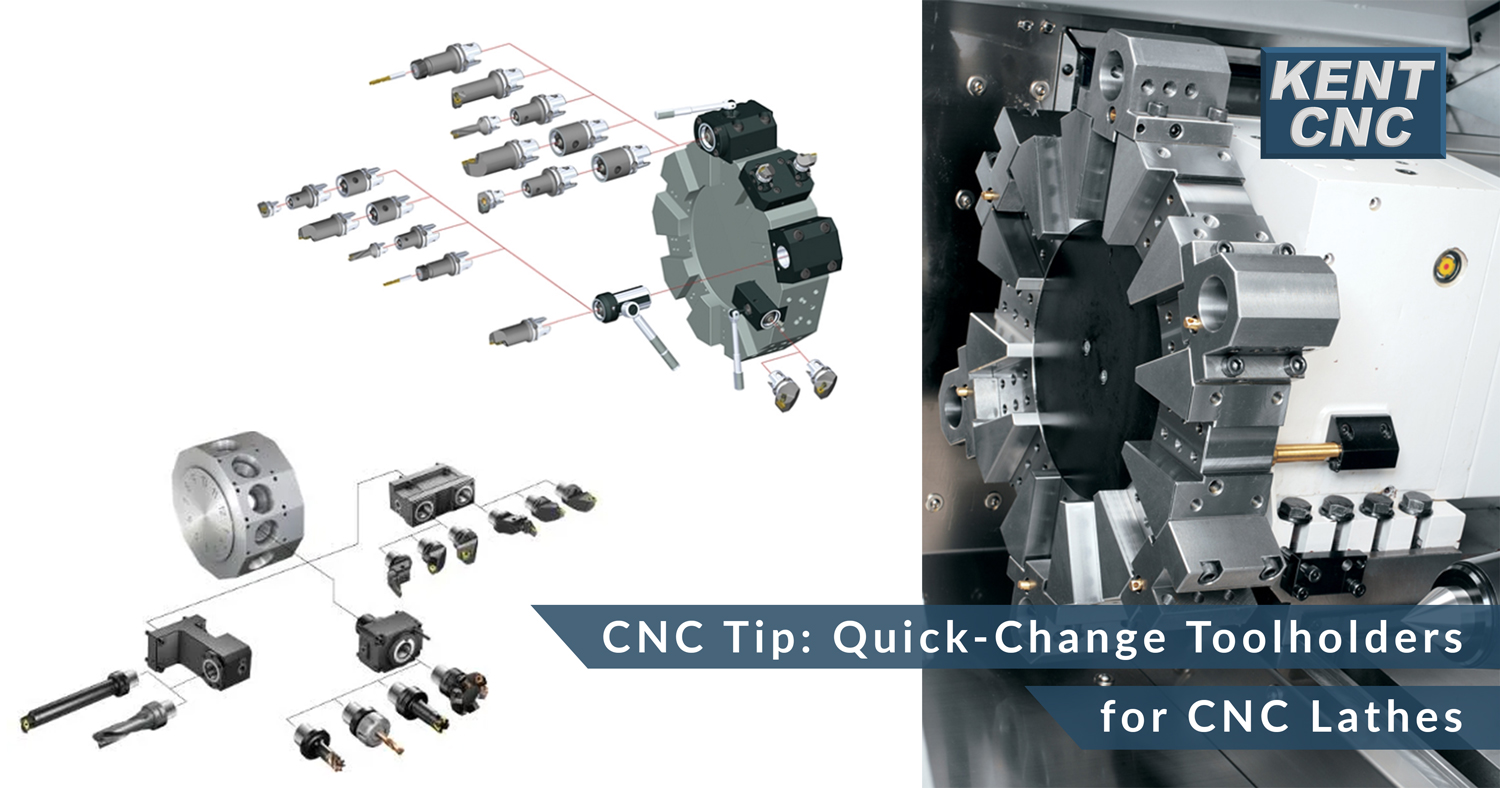

CNC Tip: Quick-Change Toolholders for CNC Lathes

In a recent article about CNC Toolholders, we compared traditional “steep taper” milling machine toolholders to their dual-contact HSK and Big Plus alternatives. This time, we'll explore the CNC turning equivalent, a.k.a. quick-change toolholders. As their name suggests, these aftermarket devices make swapping out a broken drill or worn turning tool fast and easy. The result [...]