10 Reasons to Buy Kent CNC Compact Vertical Machining Centers

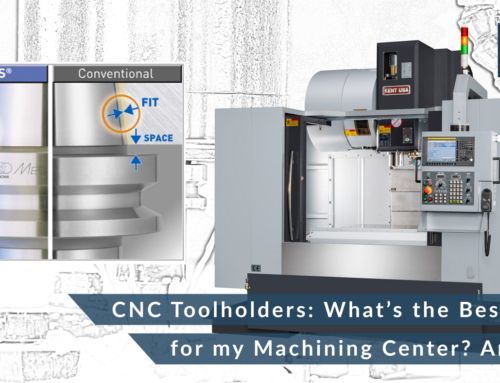

Kent CNC KVR Compact Vertical Machining Centers combine proven machine design with advanced technology in control and manufacturing. They are our most popular VMCs and provide you with the best value for your money. Long-lasting and durable, these machines deliver a precision-grade finish at high speeds.

Our most popular VMC series Kent CNC KVR Compact VMCs combine years of experience and best practice manufacturing to deliver VMCs of exceptional accuracy, quality and durability, packed with industry-leading features.

- Fanuc CNC Control. All machines are equipped with Fanuc controls, motors, and drives, with rapids of 1417 IPM. The ball screws are all pre-tensioned and cooled to give X, Y, and Z-axis positioning accuracies of .0002 inch and repeatability of .0001 inch.

- AICC high speed machining. Allows you to machine complex shapes more accurately at higher speeds.

- Roller Linear Ways (On all 3-axes). Roller type linear guides are used for greater load capacity and longer life on the bearing surfaces.

- High-speed Spindle Standard. 10,000 RPM Spindle with Chiller Higher RPMs and faster feed rates offer versatile solutions to our customers, which helps them complete their projects faster and become more profitable. The spindle chiller will extend the life of the spindle and ensures accuracy, increases the machine’s capacity and reduces maintenance costs.

- 15 HP Peak Servo Spindle Motor. Our 15 HP, Fanuc Direct Drive Spindle and Motor Mount is chilled and is standard at 10K RPM with 12K and 15K options. Six guide blocks are used on the Z-axis to increase stability. The control is 4/5-axis capable. A 24-station side mount tool changer is standard on most machines. This gives fast 1.5-second tool changes to reduce production times.

- 4-Axis Ready. With the ability to operate on different types of material, this allows spindle access to a workpiece from various angles.

- Six Linear Blocks on Z-Axis. There are 6-linear blocks that give more support while eliminating vibration and provides more stability when taking deep cuts.

- Chip Flush and Oil Skimmer. Chip evacuation from the frame of the machine by water jets into a chip tray keeps the area free of debris. Having oil-free coolant can also extend its usefulness and effectiveness, reducing the expense on maintenance and coolant replacement. Removing floating surface oils while aerating and refreshing coolant will extend tool life as well.

- Chip Auger. Automated chip removal increases your productivity with solutions that safely remove the waste and debris from your operations.

- Proven Kent USA Service & Support for Over 38 years. With over 18,000 machines sold in over 30 years, we support our clients every step of the way. At Kent USA, we have highly experienced sales engineers who analyze and help you determine which machine is best for your application. In addition, we have a team of machine systems engineers and technicians to help you set up your machine. Most importantly, we have the right personnel who are equipped with the tools to help you keep your machines running.

Top-notch Vertical Machining Center Service

We take pride in having the highest standards for our top-notch service. Your needs and concerns are very important to us, and we will do everything we can to meet them and resolve any issues to your satisfaction.

Our service department has experienced, skilled technicians who will answer your technical questions and in many cases, solve your problem effectively over the phone. For more complex jobs, it may be necessary to service your machine on-site. We can completely rebuild your spindle or whole machine, if necessary. We can apply hand-scraping methods to properly retrofit your new CNC controls. No problem is too big or too small. Call us and we’ll help you arrive at the right solution. The solution that’s right for you.

Our focus is to help our clients get their job done efficiently, productively and profitably. We collaborate with the best people and companies in the industry, working together with a common purpose and vision for excellence. We are successful when we help make our clients successful.

Experience KVR VMCs in Action. Schedule a demonstration with us at your nearest Kent CNC Distributor.